Realizations made by Formothane

Discover some of our fabrication projects! With various plastic and polymer materials for wide range of applications including polyurethane, nylon, phenolic, UHMW, we produce parts with best material that meet your requirements.

REALIZATIONS MADE BY FORMOTHANE

High performance chain guide

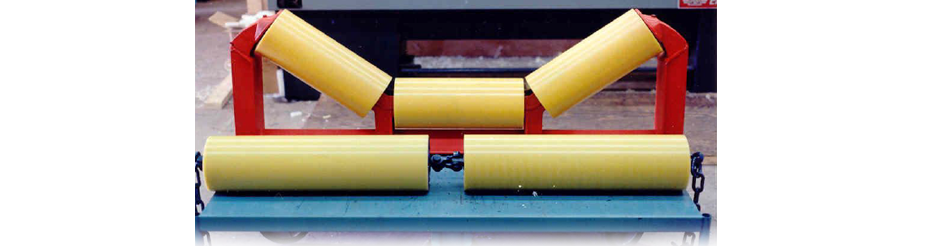

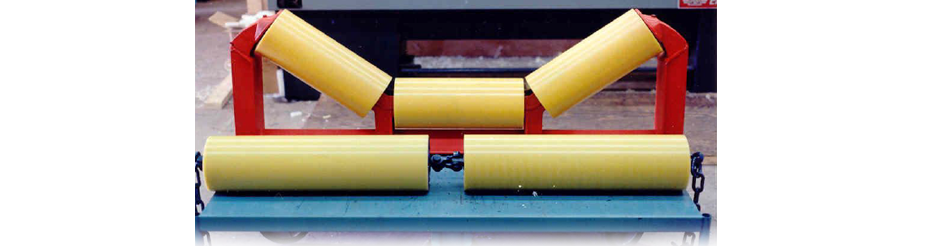

Log conveyor support

Log conveyor support

Spacer for log sorter/conveyor

Spacer for log sorter/conveyor

Magnetically detectable, impact resistant. Fabricated with three different plastic materials:

Polyurethane scraper

Gears

Gears

Wear plate

Wear plate

Polyurethane

Polyurethane

Pulleys

Pulleys

Roller guide

Roller guide

Log sorter roller repair

Log sorter roller repair

Rip saw fork

Rip saw fork

Loader pivot pin

Loader pivot pin

Chip Feeder or silo lining

Chip Feeder or silo lining

Lockout container and bin

Lockout container and bin

Sleeves for oven racks trolleys

Sleeves for oven racks trolleys

Anti-adhesive lining

Anti-adhesive lining

Conveyor belt rollers-EXU

Conveyor belt rollers-EXU

Assembly and welding of parts

Assembly and welding of parts

Mini arena separator for the youngs

Mini arena separator for the youngs

The benefits of using T-88 BLUE in chain guide include noise reduction, impact strength and wear resistance, lower coefficient of friction than the conventional chain guide, improving durability of 30-40% than if the equipment had no chain guide, and service life of mechanical components will also be increased. Available in small quantities, not to mention the saving of energy costs by decreasing the power consumption (kW/h) of engines.

The benefits of using T-88 BLUE supports include noise reduction, lightweight and higher strength than steel, impact resistance, while allowing significant improvement in speed and performance of the log conveying system. Not to mention the saving of power costs by decreasing the energy consumption (kW/h) of engines.

Magnetically detectable, impact resistant. Fabricated with three different plastic materials:

- White UHMW (non-magnetically detectable)

- Black UHMW with metal particles (magnetically detectable)

- Red Polyurethane with steel particles (magnetically detectable more effective)

Using polyurethane scrapers include many benefits. Polyurethane scraper are the first choice of most of our clients for their quality, service life as well as their cost. In addition, it is possible to add ceramic ball, to increase the service life in applications operate in harsher environments. Scrapers can be fabricated in any form or key.

Nylon replaces successfully metal in fabrication of gears used in the pulp and paper dryers. The gears fabricated by Formothane allowed to reduce noise significantly as well as reduce or even eliminate lubrication. In some cases, we fabricate gears with a reusable steel core and nylon tooth.

Different types of polymer wear plates can be used in pulp and paper sector and sawmills. They play a significant role in cost saving and effectiveness, because the replacement of bronze by some nylon grades greatly improved the productivity of some equipment.

We are in an era where all want quality, durability and versatility for their products, and at the lowest possible cost. The casted polyurethane meets these expectations, because it adapts to different applications, specific properties and strength required for each part. It takes the form, color and hardness you need. Polyurethane is an excellent material for the exact reproduction of parts in variable quantities and repetitive accuracy.

Low coefficient of friction and good abrasion resistance make Nylon an ideal solution for the fabrication of pulleys. The nylon allows to reduce or even eliminate lubrication. It also allows a significant decreasing of steel cables wear which promotes noise reduction caused by friction. Another significant advantage is that nylon is 7 times lighter than steel and will not rust.

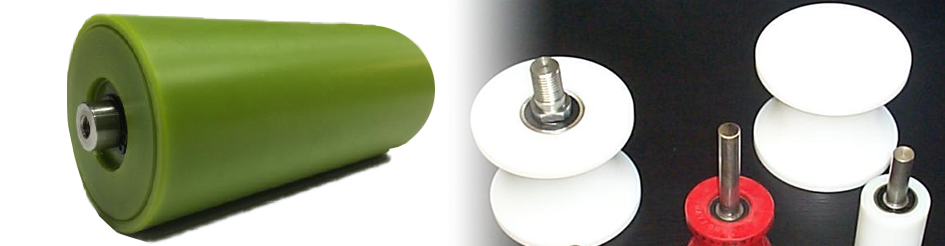

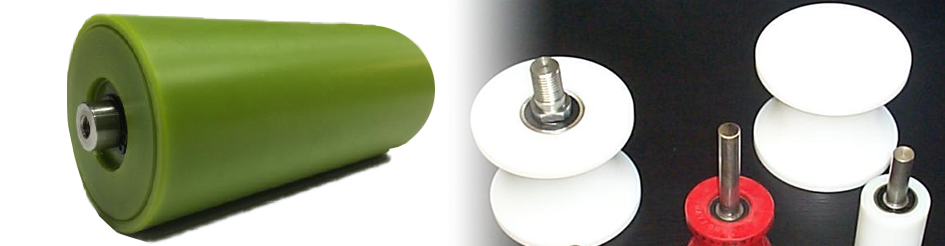

Our rollers guide are available in various materials including: UHMW, Nylon or Polyurethane. Thanks to their low coefficient of friction, they do not damage the rubber belts. We can fabricate other models according to your specifications.

> Click here to view the technical specifications of our roller guide.

Rollers could be repair or replace in applications where wear is a concern. Replacement materials are as strong as the original material.

We could produce all types of forks. Composite material offers high strength to protect the parts in contact with the phenolic.

Material available according to your dimensions, repair needs and ease of installation by your machinery mechanics.

Chip feeder or silo lining in T-88 blue are wear resistant, lighter, flexible and with higher abrasion resistance than steel. Lining can be done with 4' X 10' sheet or tailor-made by our CNC machining department.

We could provide different models and sizes of lockout bins and containers adapted to your needs.

Nylon is the perfect material for applications of heavy load bearings and low rolling velocity. With an exceptional wear resistance, it is used here as sleeve for oven racks trolleys, in mining sector. It internal lubricant enables to significantly increase the service life of all components in contact with the sleeve. Nylon outperforms bronze by its cost, its weight as well as service life of all other parts of the equipment.

Chutes originally built in steel, oxidize easily and hinder sliding. Chutes and containers of various sizes are made with different polymers. The use of UHMW, PVC, HDPE or other plastic materials allows to reduce corrosion caused by chemicals.

Designed and developed by Formothane, conveyor rollers are covered with UHMW-PE EXU, to provide an unequalled smoothness operation, prevent the wear of belt and eliminate corrosion and deterioration of the rollers. Non-adhesive rollers are unaffected by humidity and temperature change.

Formothane fabricates and repairs parts according to your specifications and needs.

Formothane fabricates mini arena separator.

Most of the improvement work of industrial components are made in our workshop. Our facilities are equipped with all relevant machinery and tools in which Formothane is committed to excellence.